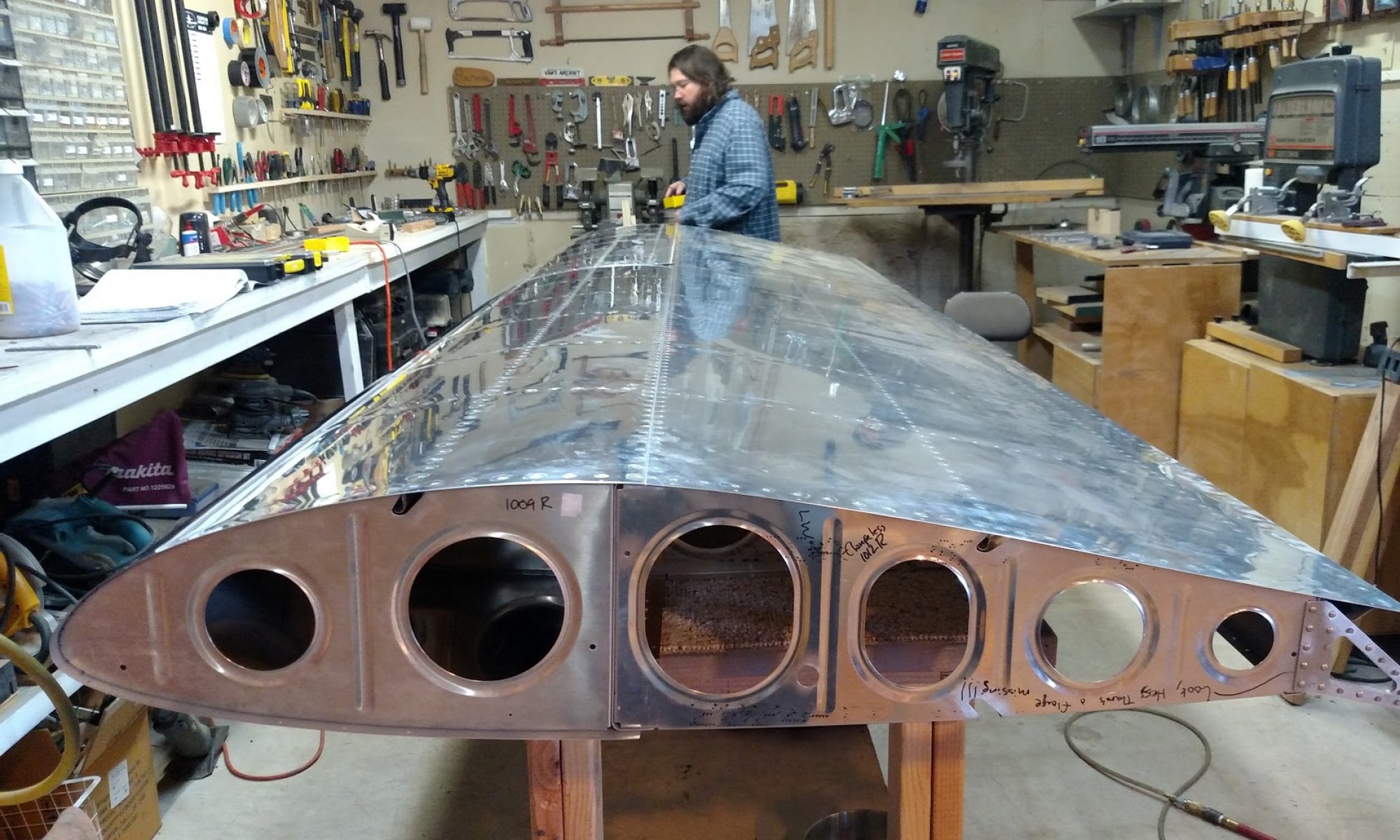

I’d forgotten what it was like to spend hours making aluminum dust. I’m now reminded, and while it’s boring, it’s still better than Proseal.

Two new mistakes: Trying to rivet with a squeezer in such a way that the yoke gap appears plenty big enough until you squeeze a rivet and a rib flange all at once. And then countersinking the wrong side of a $5 piece of aluminum.

I’m trying to make peace with the fact that I’m simply going to screw stuff up. I should rejoice that I only made $20 worth of mistakes today.

Also, the fuselage has been ordered. There’s an 8 week lead time (I suspect maybe longer this time of year), so the plan is that we should be able to mostly complete the flaps and ailerons in that time frame. And get the wing bottom skins all ready to rivet. We won’t actually rivet them until we get the wing wiring and autopilot servos installed.

All in all, we’re making reasonable progress. If we keep working on it like this, I think we’ll probably take another year to finish the airframe, and then another 2 years to finish everything else. It’s entirely possible we start putting in a lot more time when the goal gets near.

Berck: 5 hours