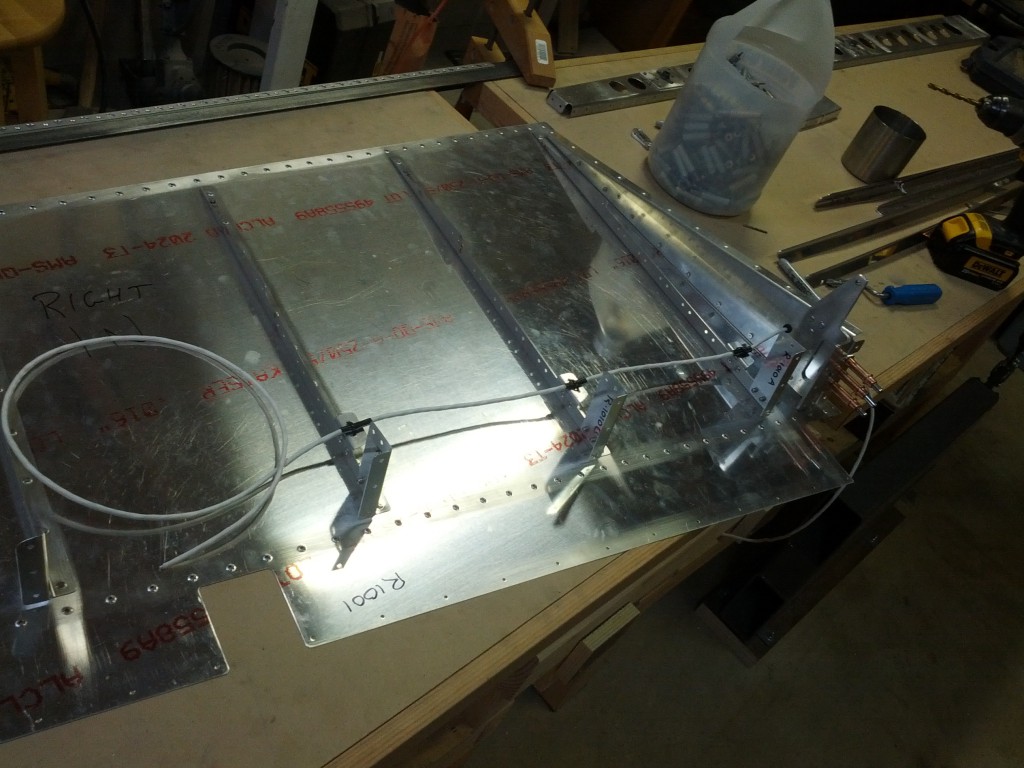

Very happy with our progress this weekend. I worked by myself today, which definitely means things go slower than when there’s help. So many cleco, and nary a cleco vixen in sight:

I also had to drive to the Woodland Park Do It Best Hardware Store (and Aircraft Supply) to acquire a long enough 1.25″ dowel to roll the leading edge. I had two 1.25″ dowels, but they really weren’t long enough. I forget to take pictures, so all you get is completed rudder at this point.

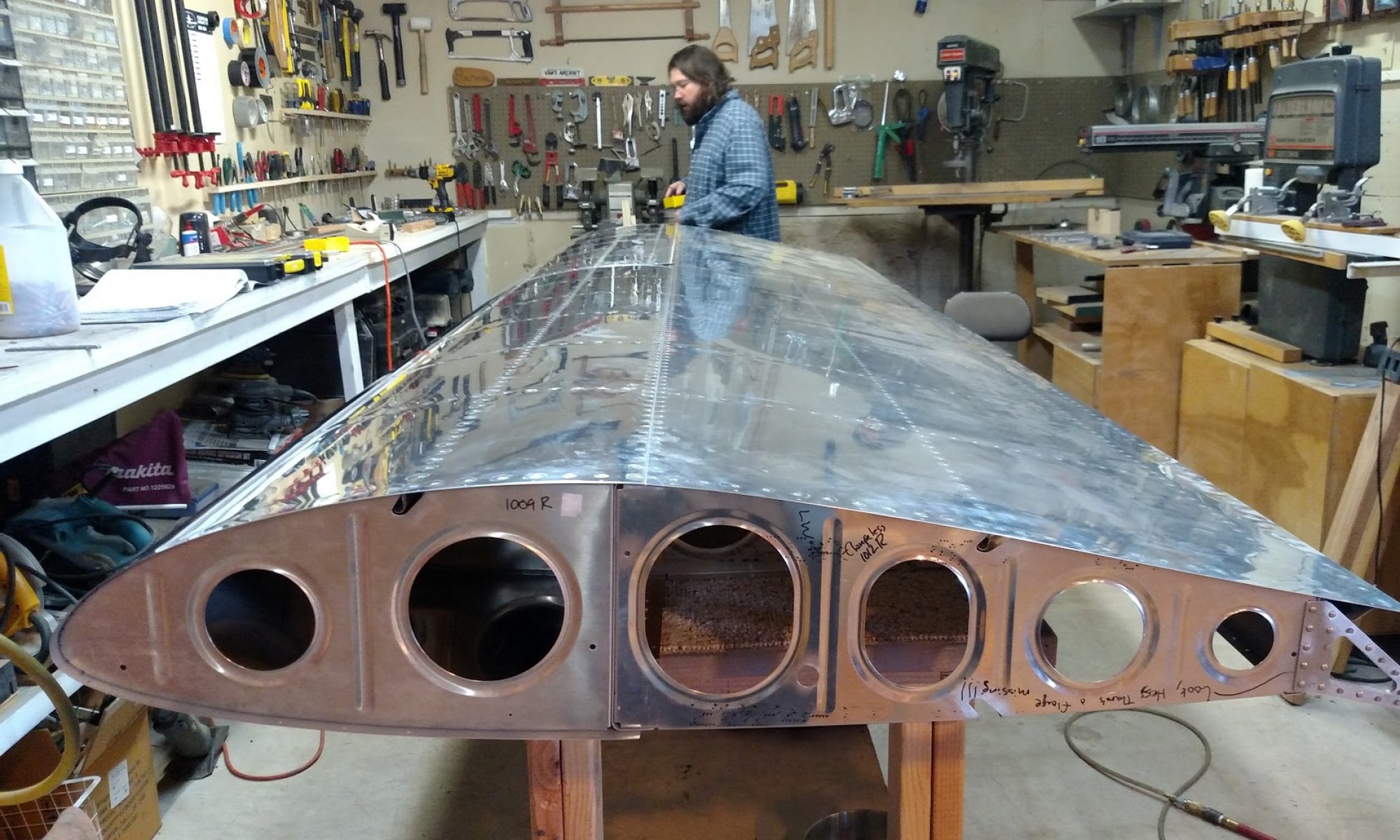

And, finally, with a Miata for some scale:

We still need to do the rudder trim, but we need to order the servos and such first. In the meantime, it’s on to the horizontal stabilizer. We need to clear off some room on those shelves before the wings arrive! (The only reason we’re ordering the wings is that prices go up April 1. With a 10 week lead time on them, we may be ready for them by the time they arrive, though.)

Berck: 9 hours.