I realized last night that I countersunk a hole I wasn’t supposed to.

The directions were very clear. They said not to countersink any flange holes on the VS-1003 which correspond to holes that you marked on the skin in a previous step not to dimple. Only, I couldn’t find any holes on the VS-1003 which corresponded to holes that I marked on the skin. I checked several times. I went back and read the instructions again, and checked the holes that I marked. I read the instructions again. None of them lined up.

It wasn’t until I was dimpling the VS-1002 front spar that I’d realized I’d gotten the two of them confused. There are no holes on the front spar flanges that correspond to marked holes on the skin. There *are* two holes on the rear spar. And I countersunk them.

I studied the empennage fairing attachment in the plans, which is what these holes will eventually be used for. Amusingly, it’s one of the last things we’ll probably do on the plane, using holes I accidentally countersunk. It looked like I’d drill them out to install a nut plate behind them. The empennage fairing is also not exactly structurally important, so I wasn’t terribly worried about it, but I wanted to know what the right thing to do was.

So, I wrote Vans an email asking what I should do about it. This morning, they responded with an email including a diagram confirming the holes I was talking about, and said that it was no big deal because I’d be drilling them out larger later anyway.

So, whew. I really wasn’t looking forward to buying new parts and repeating a bunch of work just because of one stupid little mistake.

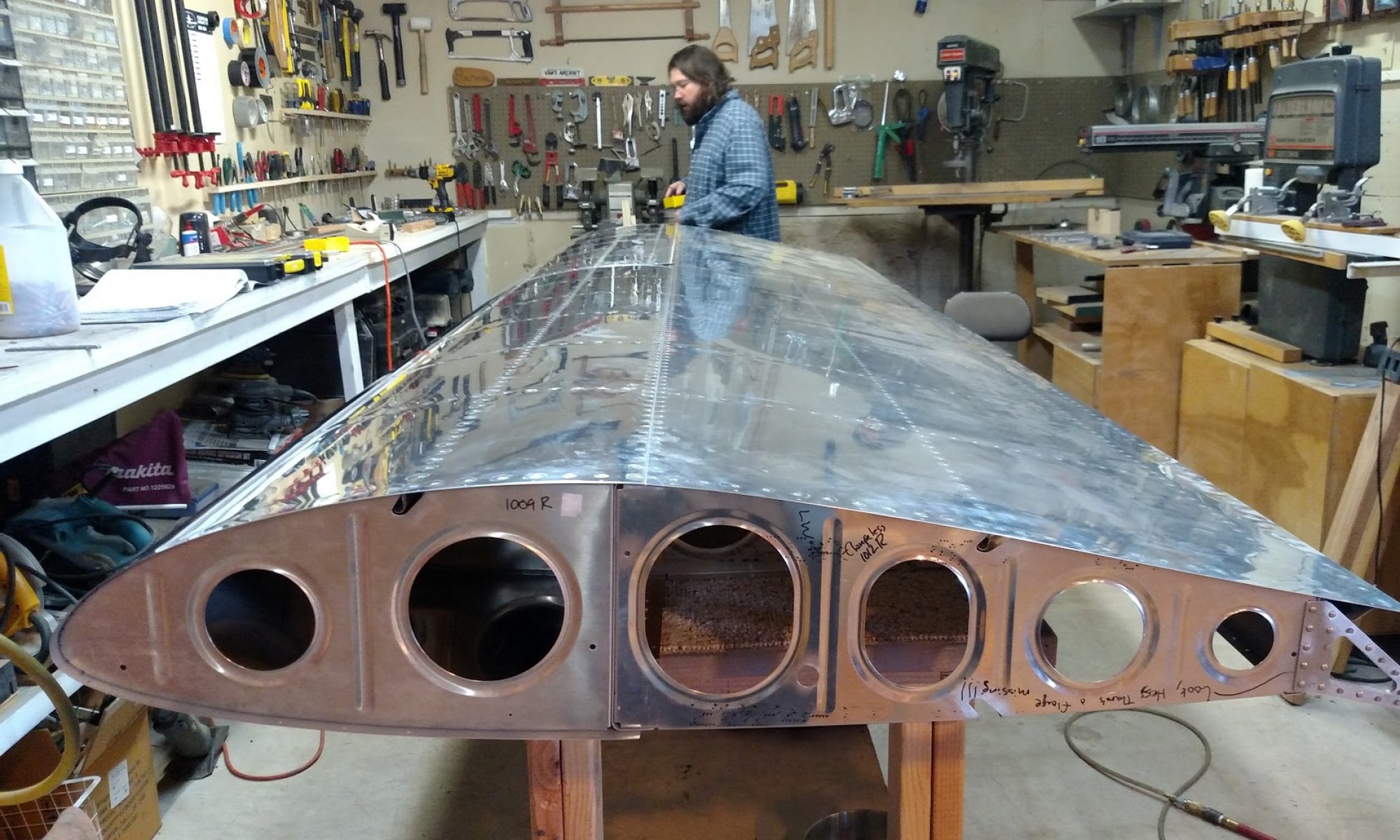

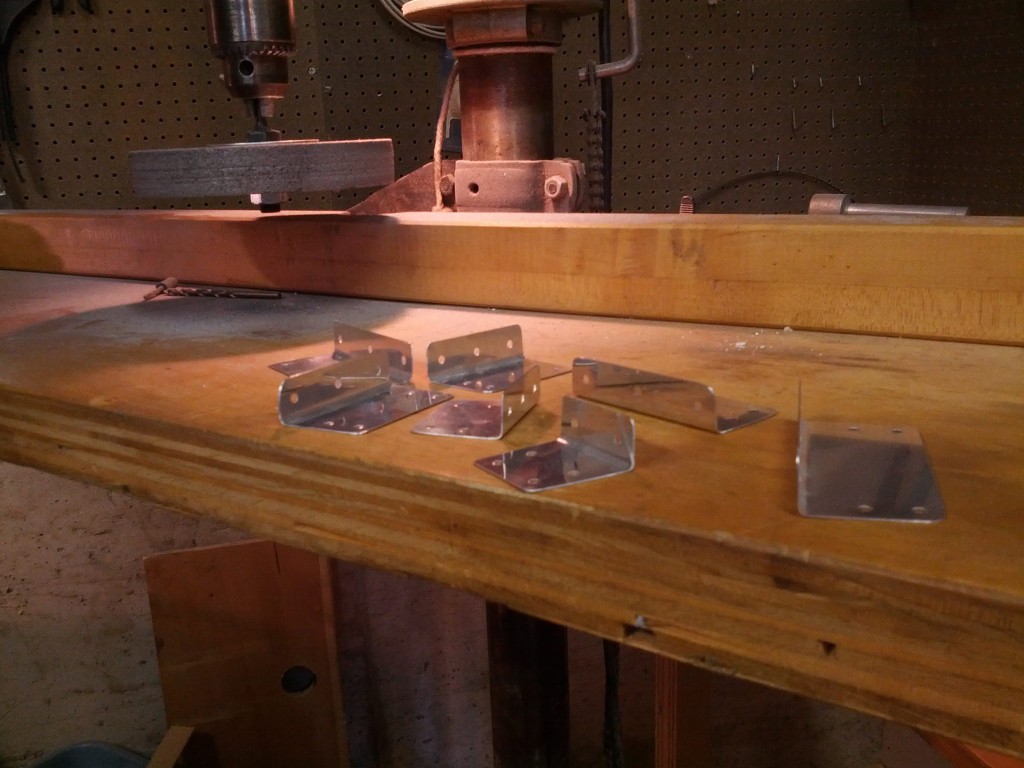

Tonight, Jonah and I worked for a couple of hours. Jonah cut, shaped and deburred some rudder bits while I riveted some backing plates.

Berck, Jonah: 1.5 hours.