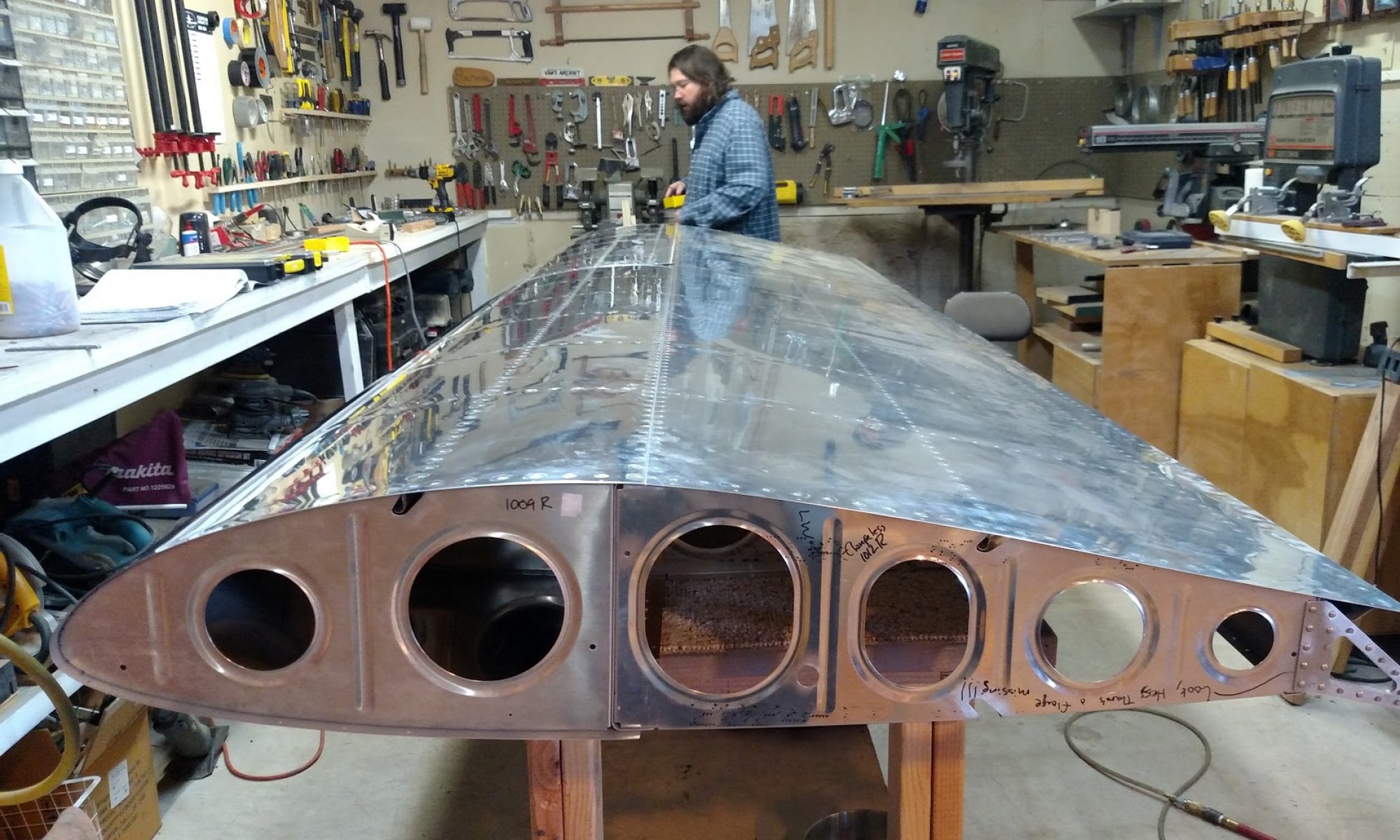

These wing spars are gold. Colored. They’re anodized. This is somewhat amusing because Van’s say that priming interior aluminum is unnecessary, but the spar is apparently worth anodizing. They’re also probably the single most expensive bits of metal on the plane. If we mess them up, it’s $2000+. Let’s not mess them up.

And they’re long. They’re 11’11”. Apparently that wasn’t long enough, so the first thing in the directions for the wings is to make them longer. Now they’re 12’5″. Why they couldn’t just be that length to begin with, I have no idea. I’d like to know.

Today, lots of deburring, and then some drilling of J-channel. Apparently the giant wing spar isn’t stiff enough on its own, so it needs some J-channel. This strikes me a little like being worried about the integrity of, say, the Golden Gate bridge, then applying some duct tape to the side of the bridge and saying, “oh, it’s good, now!” It’s clear I’m no mechanical (or aeronautical) engineer, which is why I’m building a plane from a kit.

The J-channel also, inexeplicably, overlaps. Which is ugly. So, I guess it’s like running out of one roll of duct tape while taping your bridge, then overlapping a second roll.

But it’s a kit with very specific directions, so I’ll just keep following the directions. Soon comes the dreaded countersinking of the wing spar. I’ve already screwed up several things countersinking, so I was already worried. Now I’ve found out that if you countersink these holes too much, the solution is to buy a new spar. So now I’m even more worried. I think I’ll make Randy do it.

Here are the spars, one of them with some J-channel installed with lots of holes. The next step is to remove the J-channel and set it aside. We’re wondering if the whole step is some sort of Zen koan.