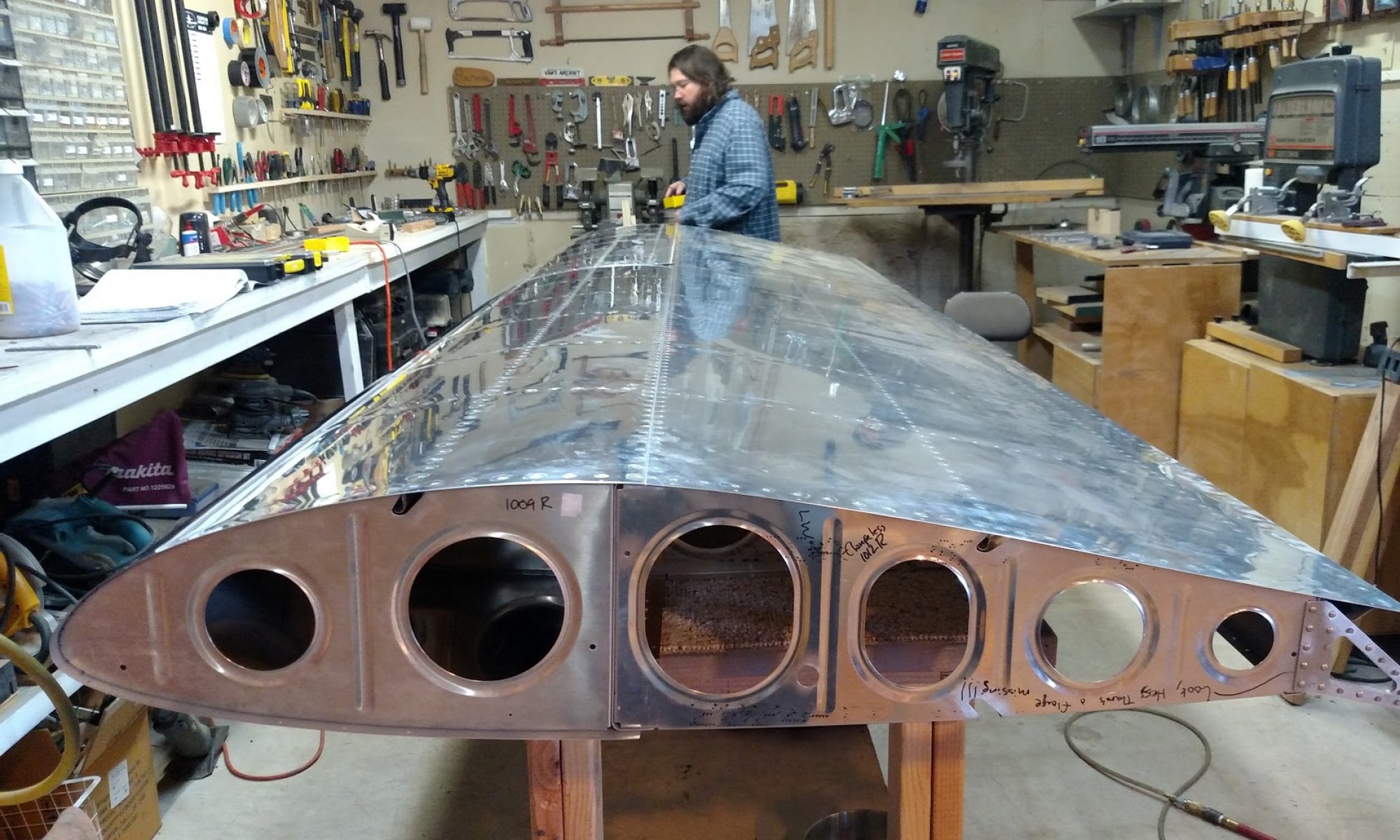

300 more clecos arrived today. I went out to the garage and clecoed with glee. Right up until the point I realized I still didn’t have enough clecos to do every hole.

I don’t know that I need to cleco every hole. I certainly feel better with every hole clecoed for both drilling and riveting: that way I know it’s absolutely the best I can do. But every other hole is probably good enough?

That frustration was nothing compared to the frustration of using the angle drill for the first time.

First: I don’t think the bits that Jay left us with for his angle drill are terribly sharp. But it may just be my technique. I managed to wallow out one hole a bit, but did several others just fine. Then came the the pieces in the corner of the “stringer web” and “in-spar rib”. It’s simply impossible to get the drill close enough from the top. From the bottom, it could be done with a longer drill bit, or a 2″ extension. Sadly, the only extension I have is like 6″, and the only #30 threaded drill bit I have is stubby. A search of the internet indicates that there is no place locally to buy a #30 threaded drill bit, or a dual threaded drill bit extension. Apparently threaded drill bits are used by everyone in aircraft construction, and no one outside aircraft construction.

So, I was convinced that we’d make good headway drilling/deburring/dimpling this weekend, but now it’s looking like we will not. Time to order drill bits and such. And maybe more cleco’s. I would like to put in a good word for the Yardstore in Kansas. They shipped our order same-day, and it’s only 2 days by UPS ground to Colorado. I’ll be ordering from them again. Tomorrow.

Berck: 2 hours, Jonah: 1.5 hours

Ugh, angle drills.

I can’t wait until Star Trek gets here, when every tool is a little gun you point at something and magic happens 😉

Yeah, but then we’ll have transporters and they’ll just make airplanes illegal because they’re unsafe and unnecessary…

The Experimental Shuttlecraft Association will protect us 😉