It’s a good thing Randy showed up today, because there were lots of things that were way easier with 3 people.

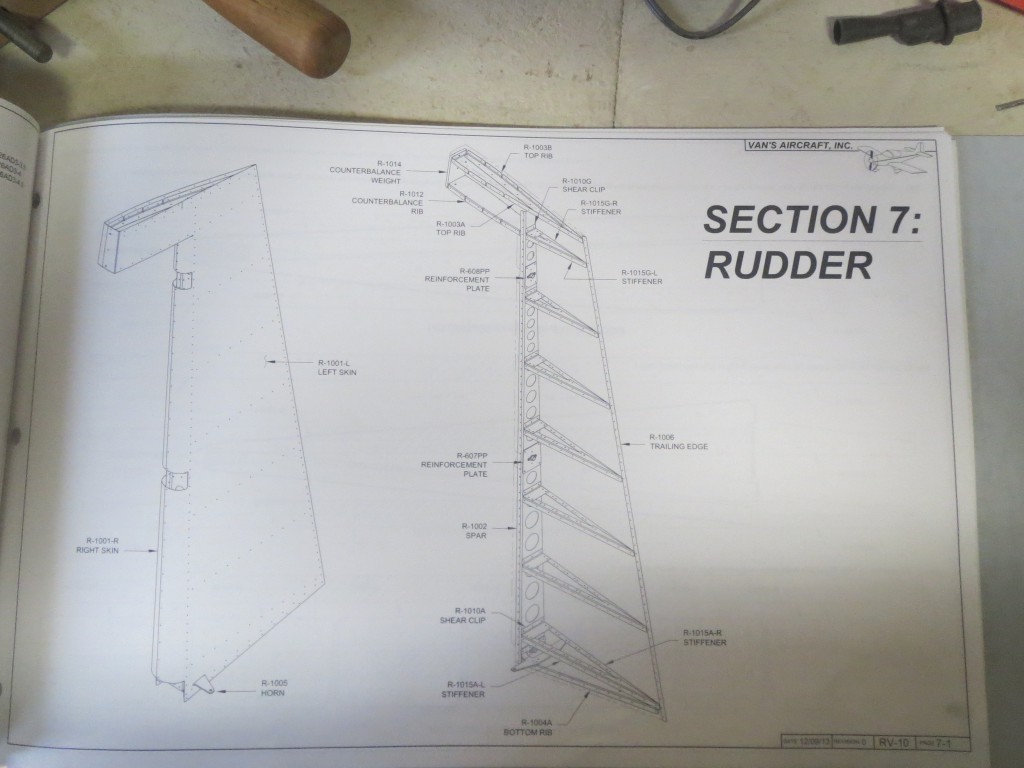

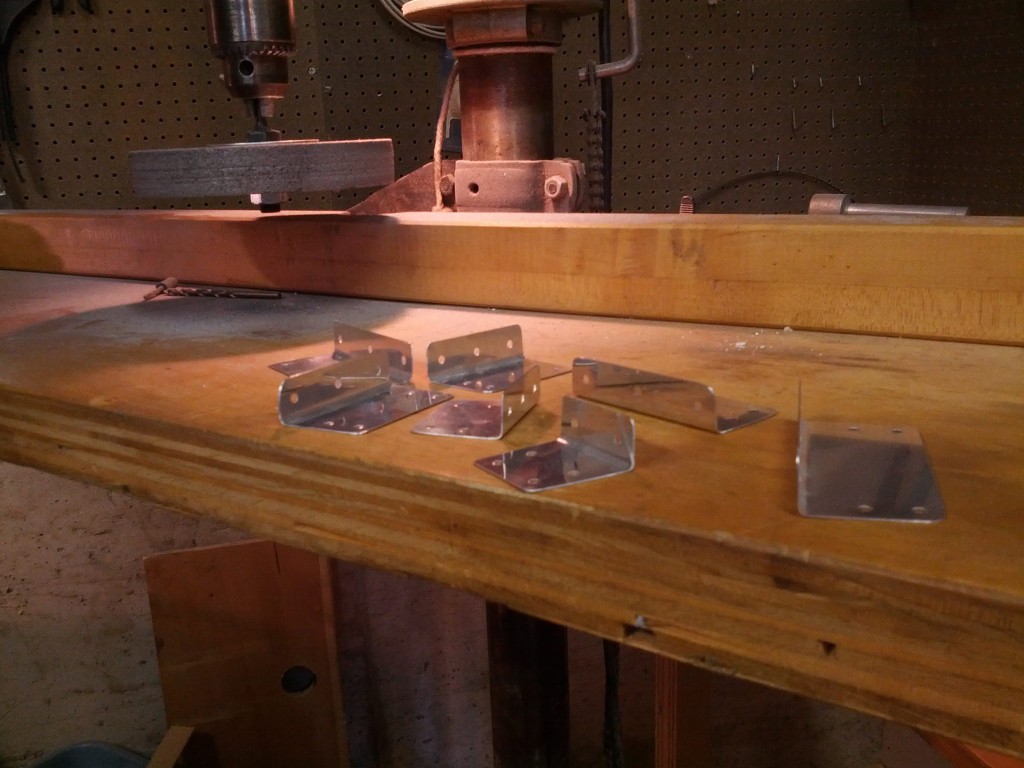

We started the day putting together the rear spar for the vertical stabilizer, with the spar caps and remaining rudder hinges.

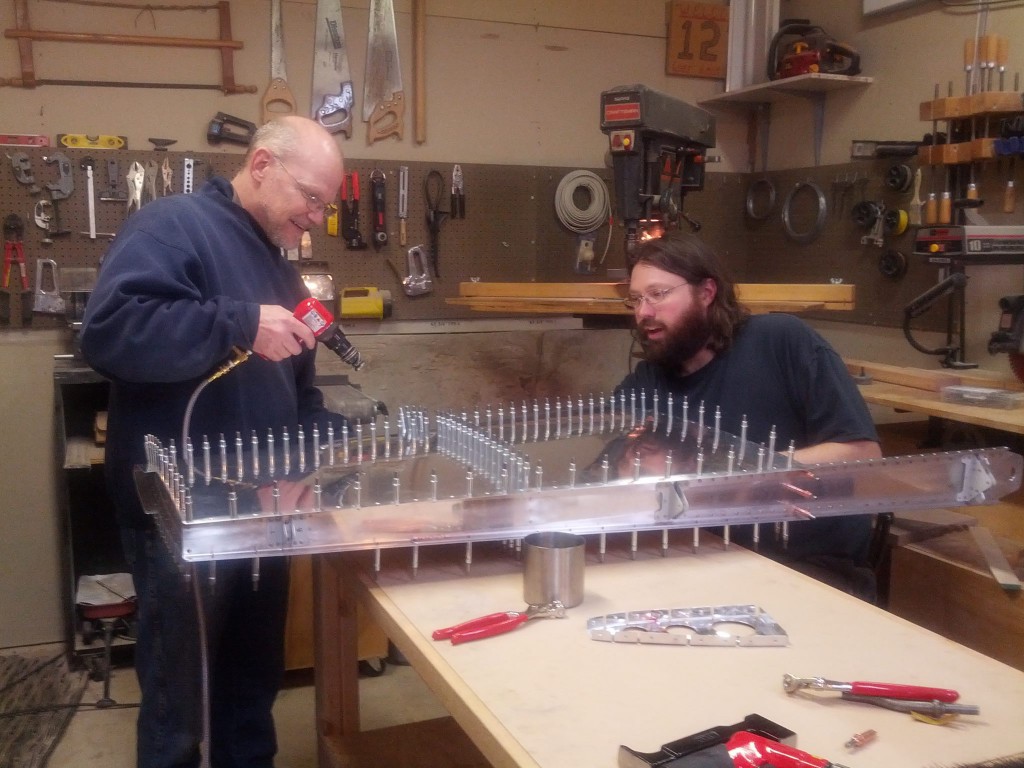

I spent much of the day shoulder deep in the stabilizer, holding a tungsten bucking bar, which after a few hours might as well have been made of white dwarf material.

Randy tried catching rivets for awhile, but you can tell from the facial expression that he did not love it, either:

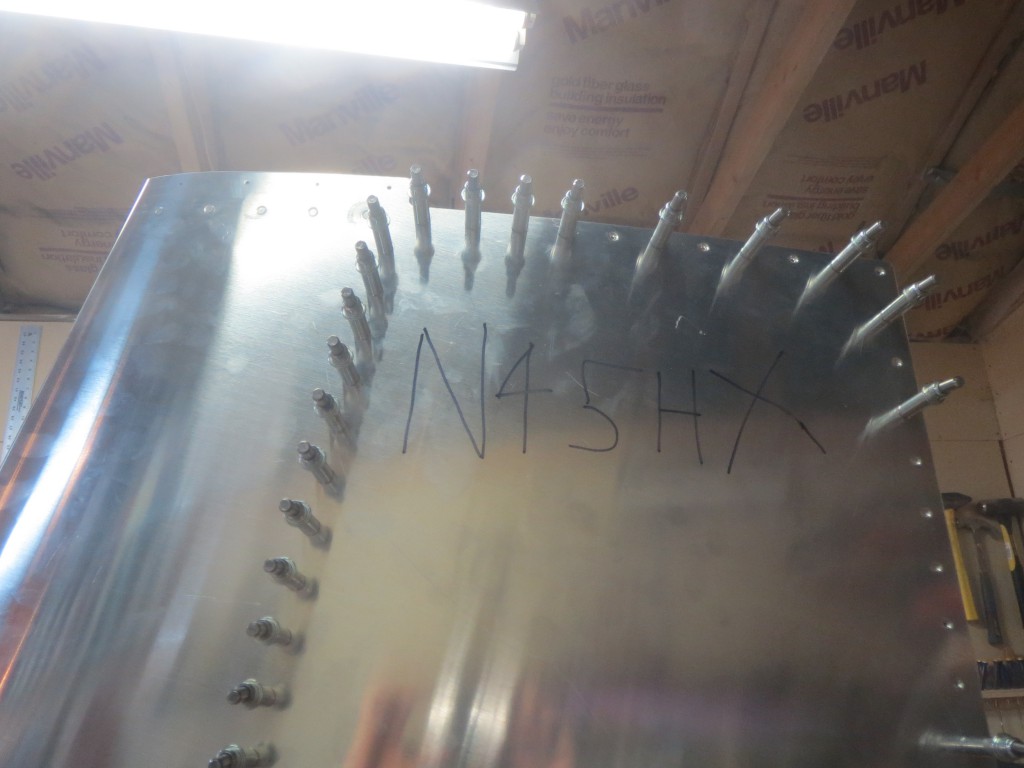

I decided that since we had both a tail and a tail number that they should be introduced.

This is the worst damage we did to the skin. Given what I’ve seen on the internet, I think we did a freakin’ awesome job.

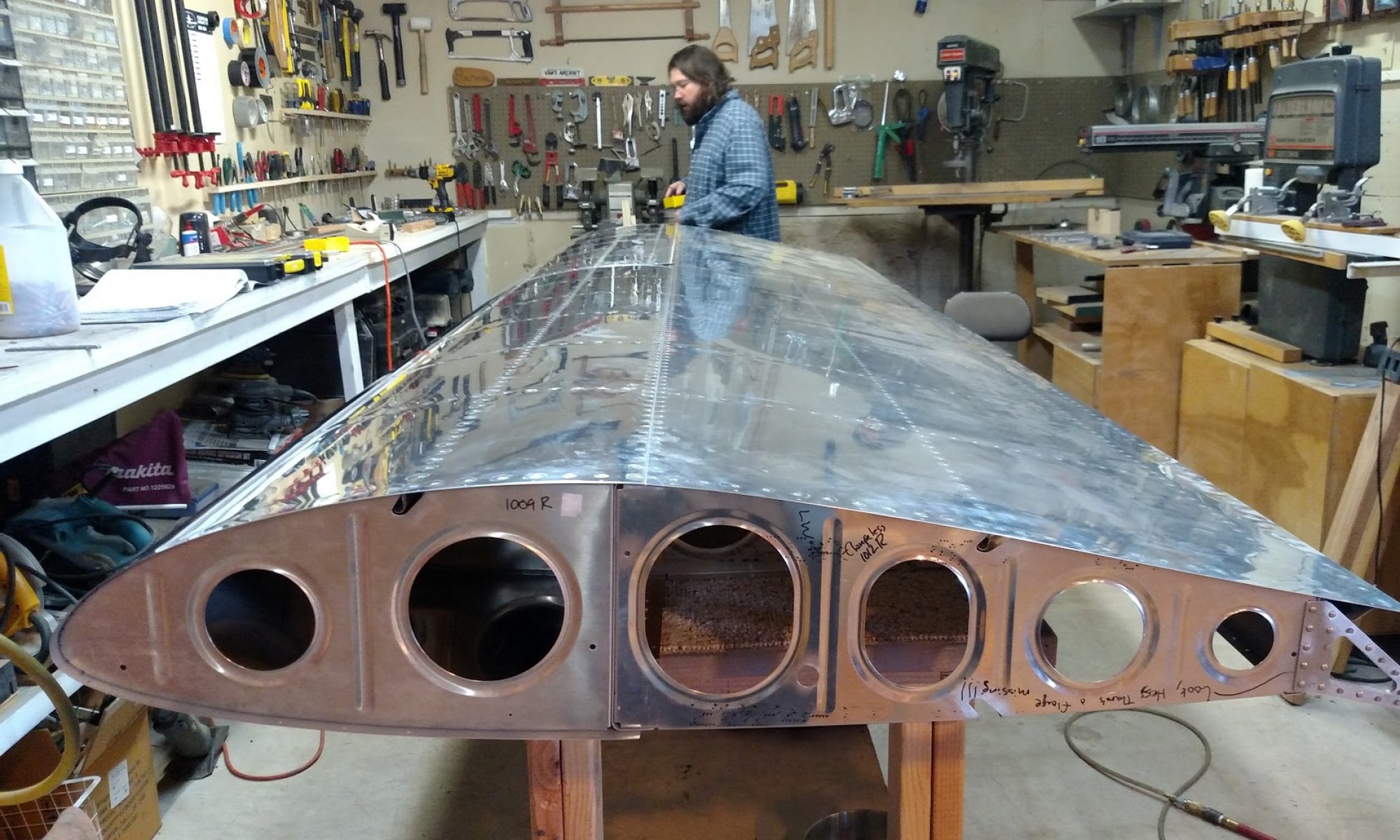

A bunch of air molecules are going to have this view in a couple of years:

Jonah is suspiciously absent from these photos because she took many of them. She was a ton of help with clecos (despite their blister-potential), and providing a fifth or sixth hand where it was often needed. Not to mention the snow-shoveling.

It feels amazing to have a completed piece of an airplane sitting your garage. Before long I’m going to go flying in something my friends and I built in my garage. Now that’s America.

Berck: 9 hours, Randy: 8 hours, Jonah: 4 hours.